Save fresh water and minimize emissions!

The UN's sustainability goal number 6 is, among other things, about managing the world's water resources in a sustainable way. Some of the goals set by 2030 are: The effects of today's actions on the future must be taken into account so that future generations can also satisfy their needs. Sustainable development requires a long-term structural change in our economic and social system, with the aim of reducing environmental and resource consumption to a sustainable level while maintaining economic performance and social cohesion. • Limit emissions of hazardous chemicals. • Significantly improve the utilization of water in all sectors. • Increase the proportion of reclaimed water and safe reuse. • Treat waste water. • Collect and use rainwater

This is something that Sørby utleie has taken seriously and has made large investments in our washrooms and the way we clean our machines. Westmatic Ab has been a very serious and listening supplier in order to be able to deliver all the wishes we had for our cleaning halls. They have built Norway's only fully automatic wash machine that can wash large construction machinery, focusing on recycling and cleaning all water. Collection and use of rainwater from all roof surfaces as fresh water supply. In addition, we have placed great emphasis on the everyday life of those who work with preparation of the machines by automating the washing process, we have separated wet, dry and noisy zones in the cleaning halls to maintain a good working environment with HSE in a special class.

The washing facility consists of

Sharing equipment therefore becomes a sustainable model which means that resources are utilized with a much higher degree of utilization. Renting is also a circular model.

The facility is designed for minimal water consumption, in the automatic machine hall recycled water is used for under-flushing, side-flushing and high-pressure arcing.

From all the roofs, all rainwater is collected into a rainwater recycling system, which is then used for final rinsing of machines in the automatic hall and high pressure in all three halls. The outgoing water that is too bad for recycling from the halls is cleaned before it goes into the municipal sewer.

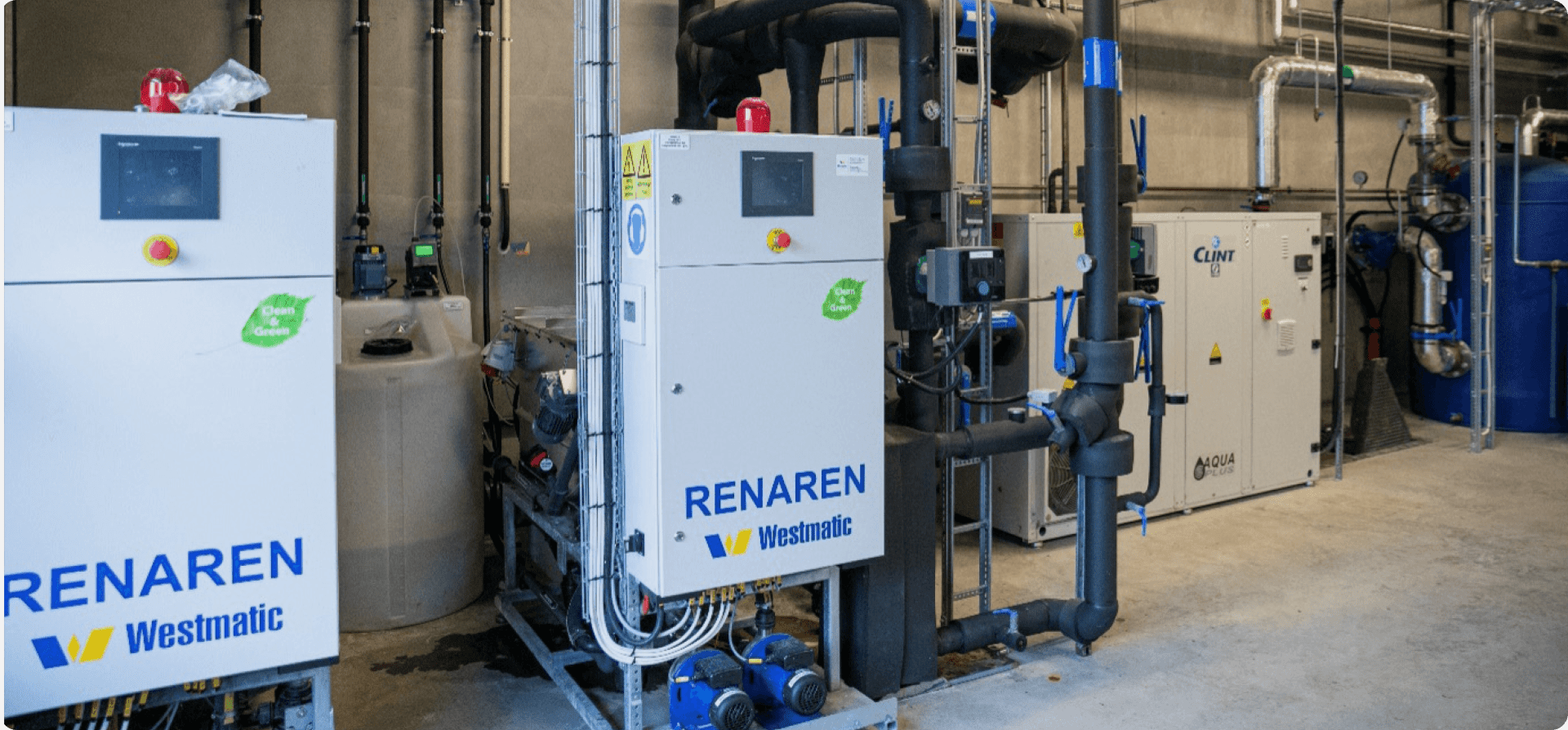

Water treatment

The water passes through hydrocyclones which act as a mechanical cleaning unit before being treated by Ozone which removes bacteria and bad odours.

After this process, more than 85% of the water can be recycled. The system is fully automatic and can be produced with different capacities, from 165 to 1200 litres/minute.

The water that is not recycled is transported on to Renaren, which is based on a unique and patented technology developed by Westmatic. The cleaner can separate and dissolve contaminants such as oil products and heavy metals in water. The contamination may be after washing or from other processes. The purifier cleans the water up to 99% and thus meets all national and international environmental requirements by a good margin.

The cleaning process takes place completely without chemicals and is fully automatic through an automatic control system. The polluting water first passes through an oil separator and then on to an electric filter. The pollution is collected in a container and the water can then be reused or released into the municipal sewage system.

How much fresh water is saved

All high-pressure functions in the automatic washing machine and all coarse rinsing run on recycled water. All hand washing and rinsing uses rainwater. This means that if there is water in the rainwater tank, fresh water consumption is largely non-existent. Viewed over an entire year, it is estimated that fresh water consumption is closer to 0 than 5% of the total water flow. If everything were to run on fresh water, it is estimated that more than 15,000 cubic meters/year would be consumed.

Less consumption of chemicals.

The washing system is designed for minimal consumption of chemicals. The machine applies a thin, even layer of detergent, which means that significantly fewer chemicals are used than when washing by hand, for example. In addition to this, much of the chemicals in the recycled water are reused during rough flushing.

The entire plant is designed to consume as little fresh water, electricity and chemicals as possible.

See video of how the washing facility is built here: https://vimeo.com/625525241

Clean and Green by westmatic and Sørby Utleie!